Collaborative areas include

Materials fabrication and characterisation

Creation of new materials and their broad characterisation is core to many reserach groups and reserachers, including: Prof Clare Grey (materials chemistry for batteries, supercapacitors and fuel cells), Dr Sian Dutton (functional energy materials), Prof Judith Driscoll (functional oxides), Dr Suchitra Sebastian (new correlated materials, emergent phases of matter). Modelling of characterisation techniques - NMR, EELS, optical spectra, IR, Raman etc. is performed by Dr Andrew Morris.

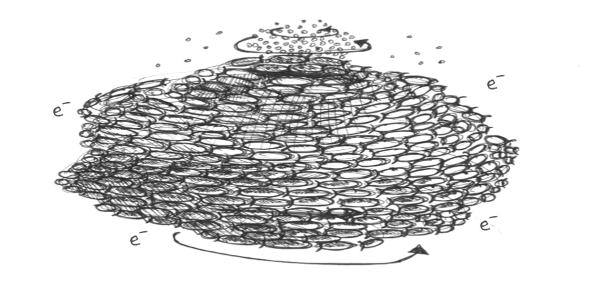

Energy materials research at the NanoDTC involves primarily transport and reactions at or across interfaces. The focus is on finding ways to produce nanomaterials that can be made with controlled architectures but also cheaply and with scalable production. Read more here.

New materials design via computational prediction

The area of expertise of Dr Andrew Morris is using computer modelling to: predict structure of materials at the atomic level, in bulk and at surfaces; discover never-found-before phases of materials and new materials; predict lattice and amorphous structure; perform high-throughput computational screening of structure databases; predict point defects and doping in semiconductors and ceramics; optimise co-doping to mitigate intrinsic impurities effects.

Technologies of Steel

Academic expertise in this field includes:

- Phase transformations: Prof Sir Harry Bhadesia leads development of solid-state phase transformation theory, and its experimental validation, in the hope of inventing new alloys and processes

- Modelling of alloys: Developing new principles in physical metallurgy and microstructural modelling to conceive novel technologies, which will hopefully lead to a better quality of life from the point of view of engineering design and the environment.

- Alloy and process design: in the context of steels for complex engineering applications. Besides bearings, this research is applicable to aeroengines, automobiles, stress-cancelling welding alloys and deep-ocean structures.

Other relevant activities

Areas selected to be highlighed in the Materials Research Exchange 2020 are listed here.

Facilities include

Henry Royce Institute facilities at Cambridge

The Cambridge Royce has fifteen advanced materials characterisation tools that are available for use by academic and industrial researchers. For full details please visit: https://www.maxwell.cam.ac.uk/programmes/henry-royce-institute

Advanced Materials Characterisation Suite

Dr Suchitra Sebastian and Dr Sian Dutton set up the Advanced Materials Characterisation Suite at the Maxwell Centre, a shared-access facility which is supported by technical staff and able to accommodate both expert and inexperienced users. This facility was funded by an EPSRC Strategic Equipment grant, with contributions from the University and the Winton Programme for the Physics of Sustainability. Equipment and methods include:

- Laue camera for crystal structure characterisation

- SQUID magnetometer for measurements of magnetic properties

- Physical Properties Measurement System (PMMS) for electronic properties characterisation

- high field, low temperature electrical and magnetic properties measurement (VERSMAG)

NanoDTC Nanoscience Research Tools

Owned by the EPSRC CDT in Nanoscience, and primarily used by its community:

- MFP-3D AFM System (Asylum/Oxford Instruments)

- Photron Fastcam UX50 on BX51

- Renishaw inVia Raman microscope

- In Situ SEM Heating Module (Kammrath)

- FT-IR (Perkin-Elmer Fronteer)

- Gas Sorption (Micromeritics TriFlex)

- Confocal inverted microscope (Olympus FV1200)

- COMSOL Multiphysics + RF and Electrodeposition Modules

Details at: http://www.nanodtc.cam.ac.uk/Resources/NanoDTCResearchTools