The Royce Battery Manufacturing Facility provides equipment for academic and commercial researchers to manufacture and process battery materials. This will bridge the gap between materials innovation and industrial collaboration. This comprehensive suite will accommodate a variety of materials and overcome difficult processing operations, including microwave manufacture, digestion, separation, drying, purifying, mixing, and washing.

Materials research for energy storage is a key component of the ‘Advanced Materials for a Sustainable Society’ vision of the Henry Royce Institute. To support the development of energy technologies that are safer, more efficient, and long lasting, we are integrating materials and accelerating their transition from early-stage discovery to impact. The suite allows researchers to investigate scalability of their materials and whether they can be safely processed. This provides a new capability to the energy materials community.

If your research interests require use of the battery suite or you have any questions on the suites capabilities and would like to discuss your experimental needs, contact Facility Manager Dr. Jung-In Lee (jil29@cam.ac.uk) in the Department of Materials Science and Metallurgy.

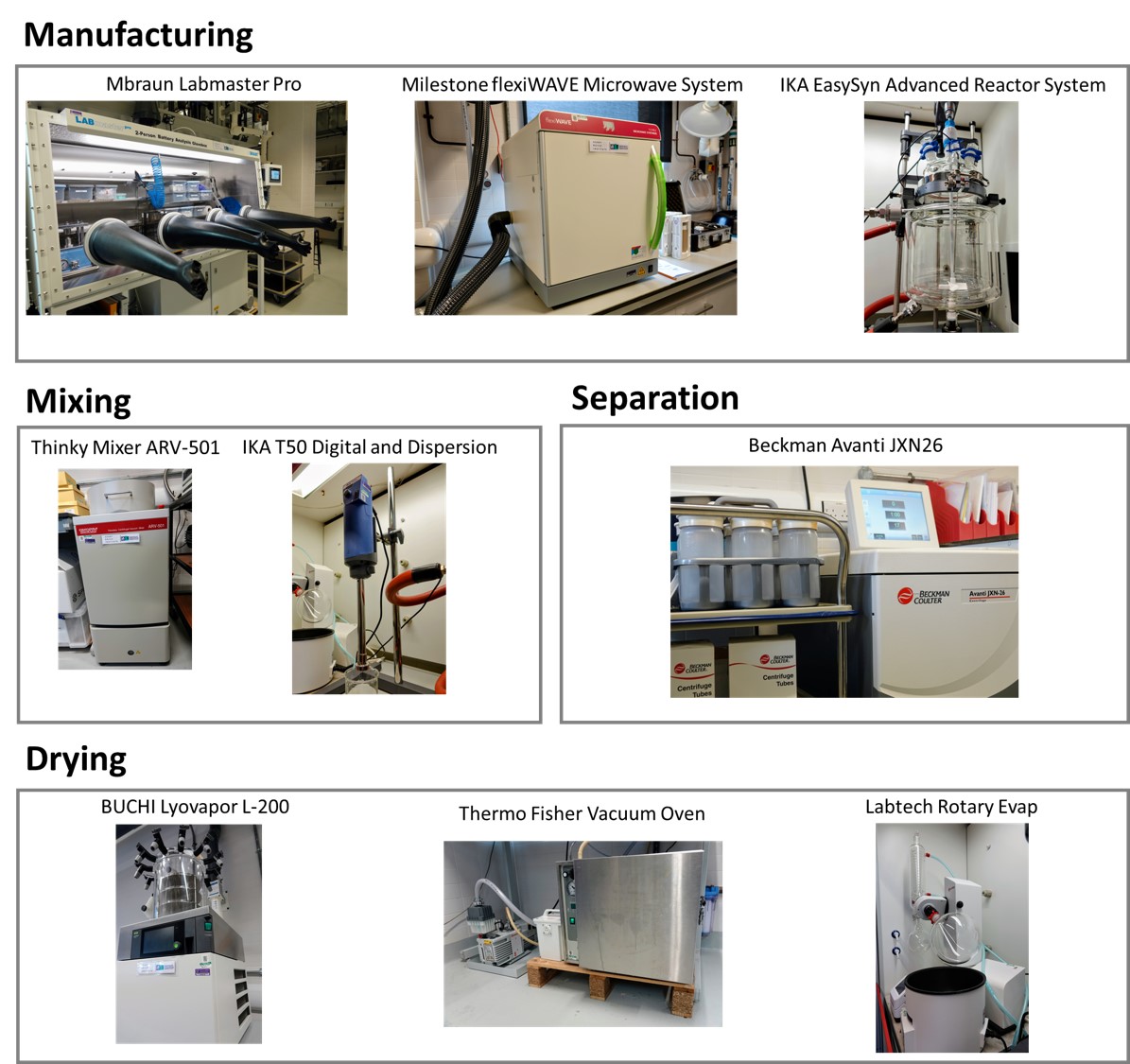

Mbraun Labmaster Pro

The glove box helps users to handle their sensitive samples under inert atmosphere.

Description:

2-user, O2 and H2O < 0.5ppm

Closed loop circulation

Working gas: Ar

Negative and positive pressure operation

Uses: Loading, handling, unloading air sensitive cells.

Milestone flexiWAVE Microwave System

The flexible microwave system allows users to synthesis and digest difficult reaction chemistries.

Description:

70L cavity, 1900W, IR sensor, camera, magnetic stirrer, exhaust system

High-pressure (1.5L, 100 bar, 300°C)

Classic glassware (0.5L, condenser)

Solid-phase (2.5L, rotating)

Uses: Digestion of electrodes, synthesis, functionalisation, coating, dehydration.

IKA EasySyn Advanced Reactor System

The reactor system is typically used for organic or aqueous synthesis.

Description:

5L double jacket, -50 to 200°C

Overhead EUROSTAR stirrer, PTFE-coated propeller

Drainage set, bottom discharge valve

Vacuum operation to 3 mbar

Uses: Synthesis, mixing, co-precipitation, filtration.

Thinky Mixer ARV-501

The planetary mixer can mix, disperse and degas your materials, in a sealed or lidless container

Description:

Maximum 700 g, 550ml capacity

Adapters down to 1g, 10ml capacity

Mixing mode; revolution 1500 rpm, rotation 867 rpm

Defoaming mode; 2000 rpm, rotation 60 rpm (attainable vacuum 0.60 kPa)

Uses: Slurry formulations and homogeneous mixing

IKA T50 digital and dispersion

The overhead stirrer can go up to 30 litres of mixture, and up to 10,000 RPM in speed.

Description:

Volume range: 0.5 – 30 L

Speed range: 600 – 10,000 rpm

Max viscosity: 5000 mPas

Dispersion element (S 50 KG HH G 45 M), H Stand

Uses: Dispersions and mixing

Beckman Avanti JXN26

The centrifuge has a maximum capacity of 6 litres and 26 thousand RPM, 82 thousand g.

Description:

Maximum capacity of 6.0L, 26,000 rpm, 82,000 x g

Temperature -10°C to +40°C

JA-25.50 Fixed-Angle Rotor, 8 x 50 mL, 25,000 rpm, 75,600 x g

J-LITE JLA-8.1000 Fixed-Angle Rotor- 6 x 1,000 mL, 8,000 rpm, 15,970 x g

Uses: Liquid-solid separation and sample processing at temperature control.

BUCHI Lyovapor L-200

This freeze dryer allows users to dry samples through lyophilisation.

Description:

6kg capacity, -55°C

3 heated shelves (60°C)

Attainable vacuum 0.04 mbar

Drying chamber or 12-port manifold connection

Uses: Drying samples before slurry or electrode fabrication, self-assembly of composites.

Thermo Fisher Vacuum Oven

The Vacuum oven dries samples at temperature and under inert gas.

Description:

65L

Jacket heating; 220°C

Attainable vacuum 3.5 mbar

Purge needle valves

Stainless steel, aluminium shelves

Uses: Drying coated or slurry formulations but can be used for curing, vacuum embedding, and plating.

Labtech Rotary Evaporator

The rotary evaporator assists with drying of more solvent heavy samples, or purification.

Description:

20 - 300 RPM, 180°C

Evaporation flask 3L, receiving flask 1L

Recirculating chiller, vacuum controller (1 mbar)

Uses: Removal of selective solvents from your samples by evaporation.